Product overview

The intelligent electric contact liquid level display controller produced by our company adopts the special integrated circuit developed by ourselves and customized by Japanese integrated circuit manufacturer. The liquid level switch signal can be accepted. The liquid level value of each liquid level switch can be set separately. The current liquid level can be indicated by LED digital form and light bar, and can be connected and communicated with the computer. It is suitable for matching with various electric contact liquid level meters and floating ball liquid level meters, and is used for the measurement and display of boiler drum water level and other liquid levels.

Main performance

1. Input at most 32 connection points, which can be configured arbitrarily.

2. It has two groups of display: digital display and light column display, which is intuitive and convenient to use.

3. It has 1-3 channels of transmission output.

4. Four alarm outputs can be set, more than ten alarm methods can be used, and the alarm parameters can be monitored.

5. It can provide RS485 asynchronous serial communication mode of multi host, single host and no host. Communication data validation complies with CRC-16 American data communication standard, with high reliability cycle and bar code validation.

Note: there are many additional functions available. When ordering, add the serial number and note all. Only one of 4, 5 and 6 can be added with other functions.

Display explain

1. Single screen + single analog bar

Single row nixie tube displays the measurement signal input by dry contact.

Single analog bar displays the measurement signal of dry contact input in percentage mode

The cursor shows the percentage of the alarm parameters of Sp1 and SP2 relative to the span.

2. Indicator light

A lamp or j1lamp, SP1 alarm indicator

E lamp or J2 lamp, SP2 alarm indicator

B light or J3 light, SP3 alarm indicator

C light or J4 light is SP4 alarm indicator light

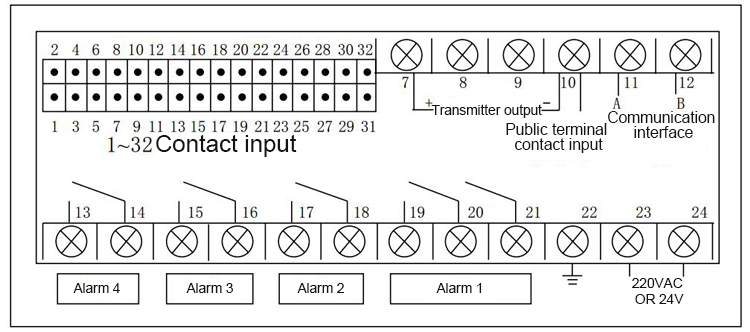

Instrument wiring

Instrument use and maintenance

1. The instrument shall be placed in a dry and ventilated place without corrosive gas, and the ambient temperature and relative humidity shall meet the technical conditions.

2. Select the instrument model and relevant procedures correctly according to the needs, so as to make the user free of debugging or direct use.

3. Due to the multiple functions of the instrument, the operation procedure of B menu and correct wiring shall be set correctly according to the working conditions. If necessary, it is suggested that the user send personnel to the factory for study.

4. If the instrument is damaged due to the quality problem of the manufacturer, it shall be repaired free of charge by the manufacturer for one year.