Product overview

The XMJA-8000 Series Intelligent Flow Totalizer produced by our company adopts an intelligent instrument with microprocessor as the core, which is developed by ourselves and commissioned by Japanese integrated circuit manufacturers to customize and produce isolated professional integrated circuit. It collects most functions of various flow calculation instruments in the current automatic control system, and at the same time, it is supplemented by extensive learning, elaborate preparation and repeated debugging .This instrument has the following characteristics because of its software system

1. The instrument hardware is greatly reduced, and the system structure is relatively simple. Within the scope of user application, multiple input signals can be switched arbitrarily. With the optimized design, the process is improved significantly. There is no flying wire, no potentiometer adjustment, and all the calibration and function settings can be completed by the software through the keyboard.

2. Up to four alarm outputs can be set, and more than ten alarm methods can be used, and the alarm parameters can be monitored.

3. Two display windows, four display windows display instantaneous flow value, six display integral value, and the actual effective integral value is seven or nine display integrator. (It can be viewed after setting the conversion coefficient) the p-type also has the function of external and internal zero clearing.

4. Any complex control, adjustment, alarm, output and other functions can be operated simply by the instrument operator. After setting, password protection can be applied to make it become a fool instrument. The field operator will not be able to modify the locked parameters. It's even possible to keep operators from checking. The anti-jamming modes of nearly 100 levels in four categories set by users can adapt to various environmental interference sources.

5. Two D/A output ports can be selected to realize photoelectric isolation output of process quantity, so as to ensure the safety and reliability of the controlled system. But for 5V or 24V two constant voltage source output, can meet the needs of most auxiliary functions.

6. The instrument can also add two time timers to control the alarm time, output time and other parameters, so as to make a simple batch controller.Therefore, compared with the ordinary control flow meter, the instrument has a considerable improvement and breakthrough in various functional levels. Its reliability and stability refer to the price ratio, which is more suitable for the national conditions, and is of great significance to replace the import.

Working principle

XMJA-8000 intelligent flow totalizer is composed of four parts: measuring circuit, digital panel meter, regulator and power supply. The regulated power supply converts the 220V mains power into the stable DC voltage as the other part of the power supply. The measuring circuit changes the signals (voltage, current, etc.) sent by the flow transmitter into voltage signals after processing. After A / D conversion, the signal is sent to jc-588 special central processor for processing. It should not only be sent to the digital panel table, but also to the regulator. After comparing with the set value, press the regulator, and then output the control or alarm signal according to the regulation rule. Working principle block diagram:

Product selection

| XMJA |

—— |

Illustration

|

|

Design No.

|

8 |

8000 series instrument

|

|

Display model

|

1 |

Dual screen display

|

| 2 |

Dual screen + single light beam

|

|

Input model

|

1 |

DC current(0~10mA、 4~20mA)

|

| 2 |

DC voltage (0 ~ 5 V 、 1 ~ 5 V 、 0 ~ 2 0 m V 、 0~100mV、 0~500mV)

|

| 3 |

Frequency input

|

|

Flow model

|

1 |

Main input signal and instantaneous flow as proportion model

|

| 2 |

Main input signal and instantaneous flow as evolution model

|

| 3 |

Main input signal and instantaneous flow as proportion model , with function of small signal removal .

|

| 4 |

Main input signal and instantaneous flow as evolution model , with function of small signal removal .

|

|

Adjustment model

|

0 |

No relay output

|

| 1 |

Two relays output , respectively control instantaneous flow or accumulative flow

|

| 2 |

Four relays output , respectively control instantaneous flow or accumulative flow

|

|

Compensation model

|

0 |

Common flow model , no T&P compensation

|

| 1 |

Saturated steam : use voltage or current signal as pressure compensation

|

| 2 |

Saturated steam : use voltage or current signal as temperature compensation

|

| 3 |

Saturated steam : use PT100 signal as temperature compensation

|

| 4 |

Super-heated steam : use voltage or current signal as temperature & pressure compensation

|

| 5 |

Super-heated steam : use voltage or current signal as pressure compensation , us Pt100 as temperature compensation .

|

| 6 |

No T&P compensation ,Have display converting system setting

|

|

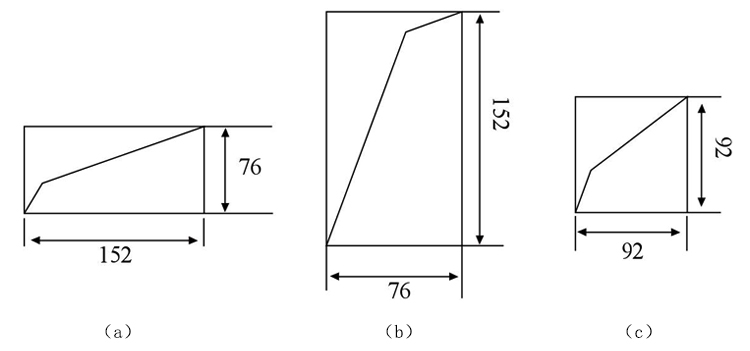

Dimension

|

H |

Horizontal 160×80

|

Portiforium 152×76

|

| V |

Vertical 80×160

|

Portiforium 76×152

|

| F |

Square 96×96

|

Portiforium 92×92

|

|

Output

|

A |

No output

|

| B |

Transmitter output 0~10mA

|

| C |

Transmitter output 4~20mA

|

| D |

Transmitter output 0~5V

|

| E |

Transmitter output 1~5V

|

| F |

Special signal transmitter output

|

|

Timing function

|

S |

No timing

|

|

With timing function

|

|

External Power 24V dc

|

P |

No 24V output

|

|

With 24V output ( As power of 2 wires transmitter )

|

|

Communication

|

T |

No communication

|

|

WithRS485 or RS232 communication

|

|

Power supply

|

K |

220V.AC

|

|

Switch power 85~260VAC or 18~36VDC、 18~ 36VAC

|

|

Technical indicators

1. Measurement accuracy: ± 0.5% FS + 1 word

2. Adjustment control accuracy: bit type: ± 0.5% FS

3. Alarm function: upper limit, twenty limit, upper and lower limit, lower return difference, double return difference, OK mode, absolute value mode, etc

4. Transmission output accuracy: ± 0.5% FS load capacity: 0-600 Ω

5. Input impedance: 0-10mA: 500 Ω, 4-20mA: 250 Ω, DC. V: ≥ 200K Ω pulse amplitude: ≥ 2.5V, frequency range: 0.01-10000hz

6. Relay contact capacity: ac220v2a

7. Power supply: AC220V ≤ 6W AC110V DC24V

8. Working environment requirements: temperature: 0-50 ℃, relative humidity: < 85%, no corrosive gas, low vibration is allowed

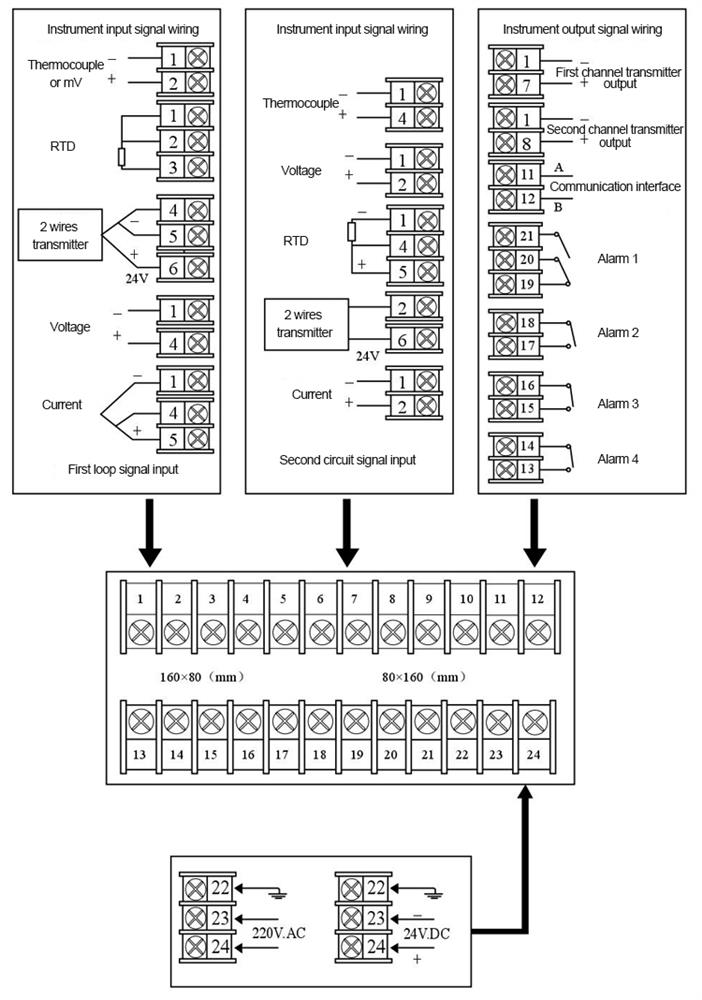

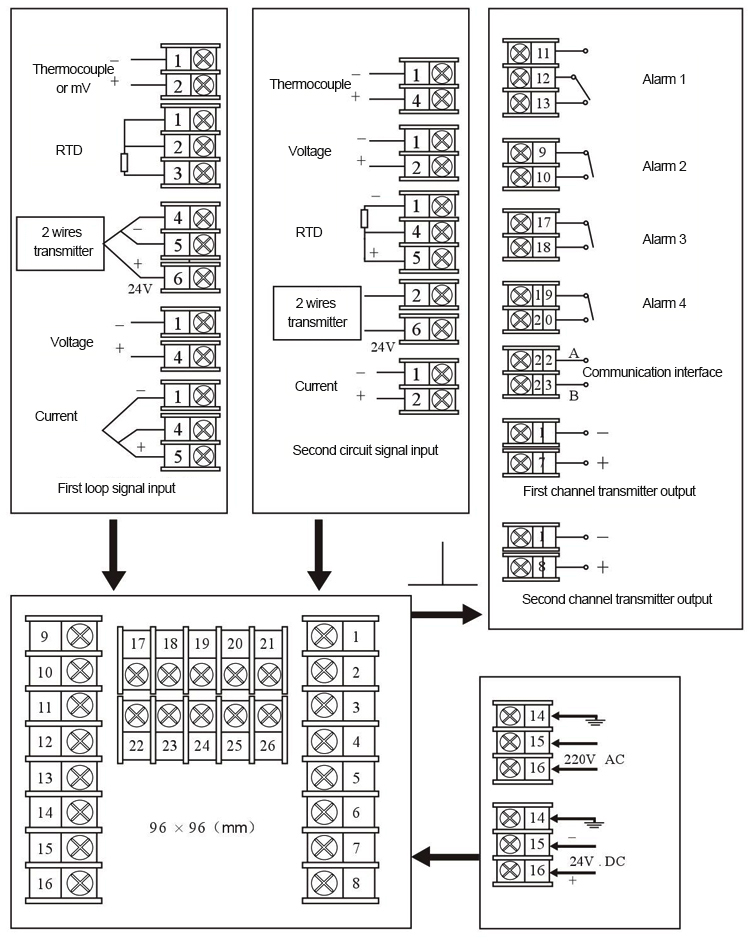

Rear panel and electrical wiring

1.

2.

2.

Instrument installation

1. Before instrument installation, check whether the instrument model, graduation number, measurement range and sensor are consistent.

2. The instruments are divided into horizontal and vertical types, including horizontal rectangular type, horizontal square type, vertical rectangular type and vertical type.

3. Opening size:

A. horizontal 152 × 76mm (see figure a)

B. vertical 76 × 152mm (see Figure b)

C. square 92 × 92 (see Figure C)