|

|

| The differential pressure transmitter Focp is suitable to measure liquid, gas, or steam flow as well as liquid level, density and pressure. 1001- B/C outputs a 4 to 20 mA DC HART signal corresponding to the measured differential pressure. Other key features include quick response, remote set-up using communications, self-diagnostics and optional status output for pressure high/low alarm. |

|

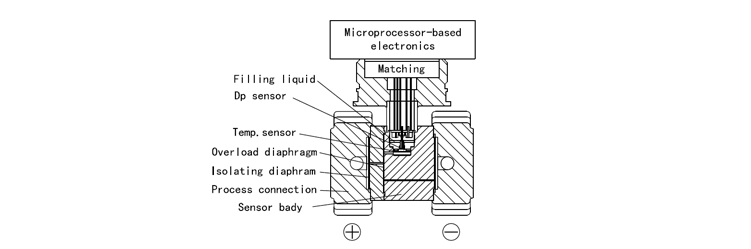

The differential pressure transmitter includes two functional units:

—Main unit

—Auxiliary Unit

The main unit includes a sensor and process connection. The completely welded sensor module is a twin-chamber system with an integral overload diaphragm, a temperature sensor and the silicon differential pressure sensor. The temperature sensor as a temperature compensated reference value to compensate for the temperature drift. |

|

Standard·Specifications

HUAHAI instruments|Strive for excellence

Committed to provide solution for field instruments

|

|

| Reference Accuracy of Calibrated Span (includes terminal-based linearity, hysteresis, and repeatability) |

| ± 0.075% |

| If TD>10 (TD=URL/SPAN): ±(0.0075×TD)% The square root accuracy is 1.5 times of reference accuracy of calibrated span. |

|

| Ambient Temperature Effects |

|

| Span Code |

-20℃~65℃ |

| A |

±(0.45×TD+0.25)%×Span |

| B |

±(0.30×TD+0.20)%×Span |

| C/D/E |

±(0.20×TD+0.10)%×Span |

| Span Code |

-40℃~-20℃ & 65℃~85℃ |

| A |

±(0.45×TD+0.25)%×Span |

| B |

±(0.30×TD+0.20)%×Span |

| C/D/E |

±(0.20×TD+0.10)%×Span |

|

|

|

| Span Code |

Static Pressure Effects |

| A |

±(0.15%URL+0.10%Span)/4MPa |

| B |

±(0.10%URL+0.075%Span)/16MP |

| C/D/E |

±(0.05%URL+0.05%Span)/16MPa |

|

|

|

|

| Span Code |

Overpressure Effects |

| A |

±0.2%×Span/4MPa |

| B |

±0.2%×Span/16MPa |

| C/D/E |

±0.1%×Span/16MPa |

|

|

|

| Span Code |

Stability |

| A |

±0.5%×Span/1year |

| B |

±0.2%×Span/1 year |

| C/D/E |

±0.1%×Span/1 year |

|

|

|

|

|

|

|

|

|

| Span/ Range Limits |

kPa |

mbar |

| A |

Span |

0.1~1 |

1~10 |

| Range Limits |

-1~1 |

-10~10 |

| B |

Span |

0.2~6 |

2~60 |

| Range Limits |

-6~6 |

-60~60 |

| C |

Span |

0.4~40 |

4~400 |

| Range Limits |

-40~40 |

-400~400 |

| D |

Span |

2.5~250 |

25~2500 |

| Range Limits |

-250~250 |

-2500~2500 |

| E |

Span |

20~2000 |

0.2~20 bar |

| Range Limits |

-500~2000 |

-5~20bar |

|

|

|

| Zero can be fully elevated or suppressed, within the lower and upper range limits of the capsule. |

|

|

|

| External zero is continuously adjustable with 0.01% incremental resolution of span. Re-range can be done locally using the range setting switch. |

|

| Mounting Position Effects |

|

| Rotation in diaphragm plane has no effect. Tilting up to 90 degree will cause zero shift up to 0.4 kPa which can be corrected by the zero adjustment. |

|

|

|

| Two wire 4 to 20 mA DC output with digital communications, linear or square root programmable. HART FSK protocol is option superimposed on the 4 to 20 mA signal. Output range: 3.9 mA to 20.5 mA. |

|

| Failure Alarm (the mode can be selected) |

|

Low Mode (min): 3.7 mA

High Mode (max): 21 mA

No Mode (hold): Keep the effective value before the fault.

Note: The standard setting of failure alarm is High Mode. |

|

|

|

| The amplifier damping constant is 0.1 sec; The sensor damping constant is 0.1~1.6 sec, it depends on the range and range compression ratio. Amplifier damping time constant is adjustable from 0 to 60 sec by software and added to response time. |

|

|

|

| Ambient Temperature Limits |

|

-40 to 85°C

-20 to 65°C with LCD display or fluorine rubber sealing |

|

| Storage and Transportation Temperature Limits |

|

| -50 to 85°C; -40 to 85°C with LCD display |

|

| Working Pressure Limits (Silicone oil) |

|

| Maximum working pressure: 16MPa, 25MPa, 40MPa |

|

|

|

| 3.5kPa abs. to maximum working pressure. |

|

| One-way Overload Pressure Limit |

|

| The maximum one-way overload pressure is maximum working pressure. |

|

| Electromagnetic Compatibility (EMC) |

|

| Look the EMC Performance Table |

|

|

| Supply & Load Requirements |

|

| 24 V DC supply, Maximum voltage limited: 42VDC, Minimum voltage limited: 12VDC, 15VDC(with LCD display) 230Ω to 600Ω for digital communication |

|

|

|

| The electrical connection is made via cable entry M20x1.5.The screw terminals are suitable for wire cross-sections up to 2.5mm2. |

|

|

|

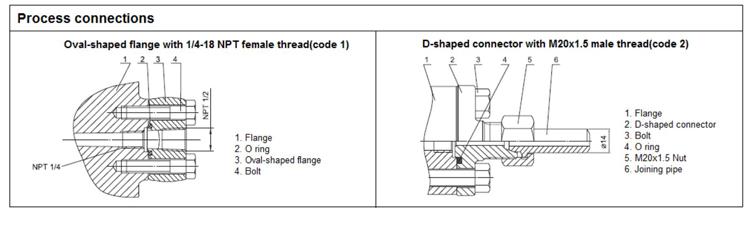

| Flange with fixing thread 7/16-20 UNF and 1/4-18 NPT female thread on both sides. |

|

|

| Sensor Body |

316L stainless steel |

| Isolating Diaphragm |

316L stainless steel/Hastelloy C |

| Nuts and Bolts |

304 stainless steel |

| Process Connector |

304 stainless steel |

| Fill fluid |

Silicone oil/Fluorinated oil |

| Process Connector Gasket |

Perbunan(NBR)/Viton(FKM)/Teflon(PTFE) |

| Amplifier Housing |

Aluminum with epoxy resin coat |

| Housing Gasket |

Perbunan(NBR) |

| Name plate and tag |

304 stainless steel |

| Weight |

3.3kg |

| Degrees of Protection |

IP67 |

|

|

|

| Items |

Test items |

Basic standards |

Test conditions |

Performance Level |

| 1 |

Radiated interference (Housing) |

GB/T 9254-2008 |

30MHz~1000MHz |

OK |

| 2 |

Conducted interference(DC power port) |

GB/T 9254-2008 |

0.15MHz~30MHz |

OK |

| 3 |

Electrostatic Discharge (ESD) Immunity |

GB/T 17626.2-2006 |

4kV(Line) 8kV(Air) |

B |

| 4 |

RF electromagnetic field immunity |

GB/T 17626.3-2006 |

10V/m (80MHz~1GHz) |

A |

| 5 |

Frequency magnetic field immunity |

GB/T 17626.8-2006 |

30A/m |

A |

| 6 |

Electrical Fast Transient Burst Immunity |

GB/T 17626.4-2008 |

2kV(5/50ns,5kHz) |

B |

| 7 |

Surge Immunity |

GB/T 17626.5-2008 |

1kV(line to line) 2kV(line to ground) (1.2us/50us) |

B |

| 8 |

Conducted interference immunity induced by RF field |

GB/T 17626.6-2008 |

3V (150KHz~80MHz) |

A |

|

Note:(1)Performance level A description: The technical specifications within the limits of normal performance.

(2)Performance level B description: Temporary reduction or loss of functionality or performance, it can restore itself. The actual operating conditions, storage, and data will not be changed. |

|

|

|

|

|

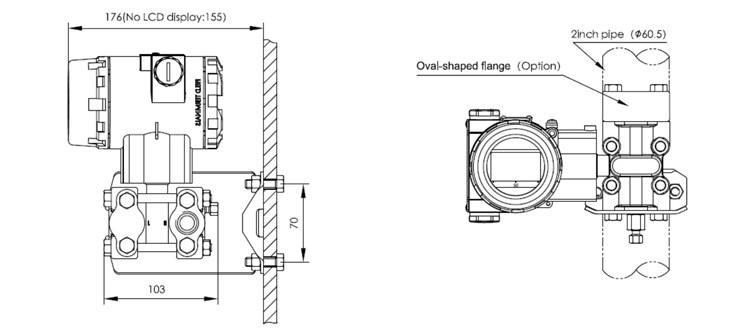

| Horizontal Impulse Piping Type(side face) |

Horizontal Impulse Piping Type(front side) |

|

|

| Horizontal Impulse Wall mounting Type |

Vertical Impulse Piping Type |

|

|

|

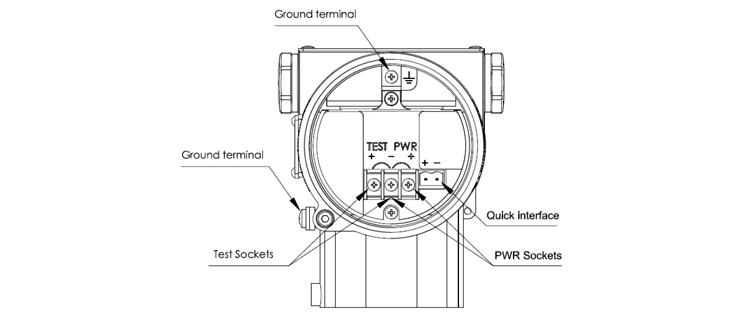

| Note:Quick interface functionally equivalent to the signal terminal |

|

|

|

|

| Differential Pressure Transmitter |

| 10 |

Output |

| |

H

N |

4-20mA with HART

4-20mA |

| 20 |

Span |

| |

Gauge Pressure |

A

B

C

D

E |

0-100Pa~1kPa(0-10~100 mmH2O)/(0-1~10mbar)

0-200Pa~6kPa(0-20~600 mmH2O)/(0-2~60mbar)

0-400Pa~40kPa(0-40~4000 mmH2O)/(0-20~400mbar)

0-2.5kPa~250kPa(0-0.25~25 mH2O)/(0-25~2500mbar)

0-20kPa~2MPa(0-2~200 mH2O)/(0-0.2~20bar) |

| 30 |

Diaphragm fill fluid |

| |

A

C |

316L stainless steel Silicone oil

Hastelloy C Silicone oil |

| 40 |

Working pressure |

| |

1

2

3 |

16MPa

25MPa

40MPa |

| 50 |

Process connections |

| |

N

B

U

D |

7/16-20 UNF and 1/4-18 NPT female thread, No relief valve

7/16-20 UNF and 1/4-18 NPT female thread, Relief valves at end of flanges

7/16-20 UNF and 1/4-18 NPT female thread, Relief valves at the upper part of the flange side

7/16-20 UNF and 1/4-18 NPT female thread, Relief valve at the lower part of the flange side |

| 60 |

Process connector gasket |

| |

N

F

P |

Perbunan(NBR)

Viton (FKM)

Teflon (PTFE) |

| 70 |

Special function |

| |

N

F

0 |

None

Square root output

Degrease cleansing treatment(Oxygen measurement must be with fluorinated oil filled capsule, Viton (FKM) gasket, <6MPa ,<60℃) |

| 80 |

Mounting bracket |

| |

N

1

2 |

None

304 stainless steel

Carbon steel galvanized |

| 90 |

Process connector accessory |

| |

N

1

2 |

None

Stainless steel oval-shaped flange with 1/2 NPT female thread

Stainless steel D-shaped connector with M20x1.5 male thread |

| 100 |

Integral indicator |

| |

N

1

2 |

None

LCD display

Backlit LCD display |

|